Links to the products featured on this post:

PHR Reverse Mount Dual Master Cylinder Kit for S14 240SX

Wilwood Compact Remote Flange Mount Master Cylinder, 3/4" Bore

Wilwood Compact Remote Flange Mount Master Cylinder, 7/8" Bore

Step 1

To do this you, obviously the dash needs to be removed from the car. Remove the dash, wiring, brake master cylinder, brake booster, pedal assembly, and any other things that might be in the way of doing the next steps. You really need to have the entire dash area pretty much empty.

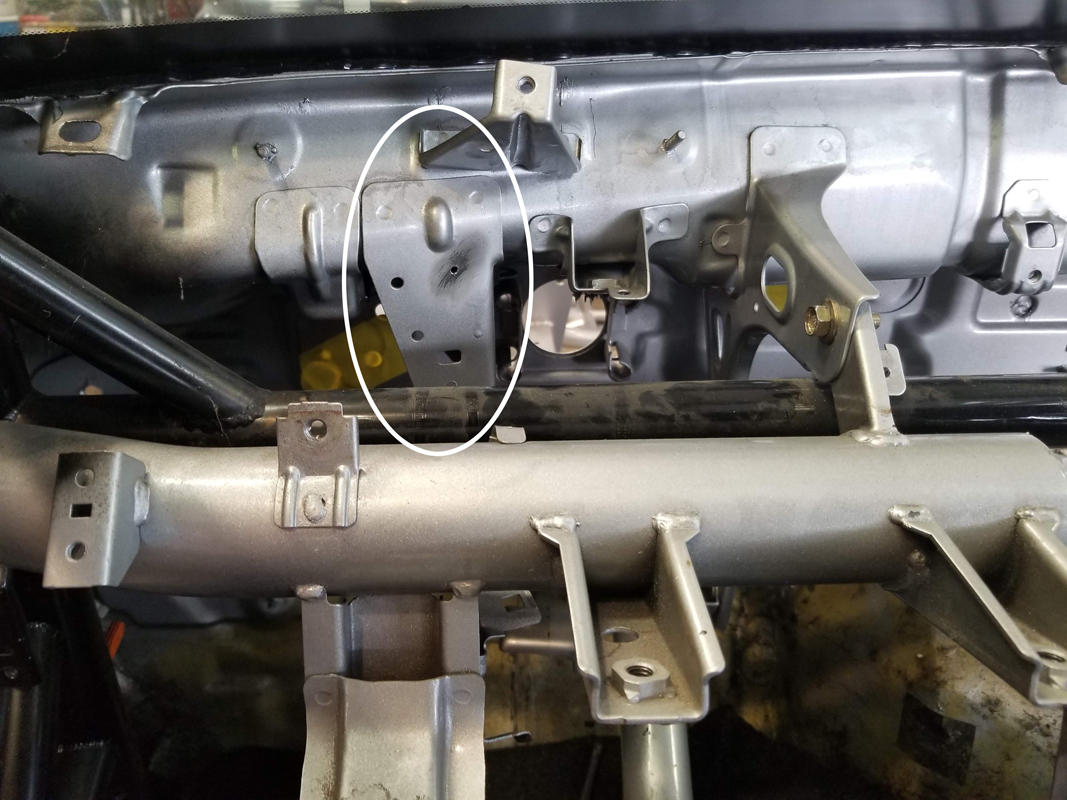

You need to remove the large sheet metal bracket on the left-hand side of the steering column that holds the steering column up.

In the picture above you can see where the roll cage dash bar is. It might be necessary to move your dash bar to a different location or height to accommodate the master cylinder kit if you already have a roll cage installed.

Make sure the steering column is lowered and no longer connected to the bracket.

Drill out the spot welds on the sheet metal bracket. The lower ones can be accessed from inside the cowl where the wiper assembly is located. You’ll need to access the cowl area by removing the wipers and plastic covering. You can identify where the spot welds are by the indentations in the sheet metal. A ¼ inch drill bit usually does the trick, but if it doesn’t fully separate, increase the drill bit size until the weld is drilled completely out. This will leave holes remaining in the sheet metal and these will have to be filled in with a sealant or welded back closed to prevent leaking.

See pictures below:

Step 2

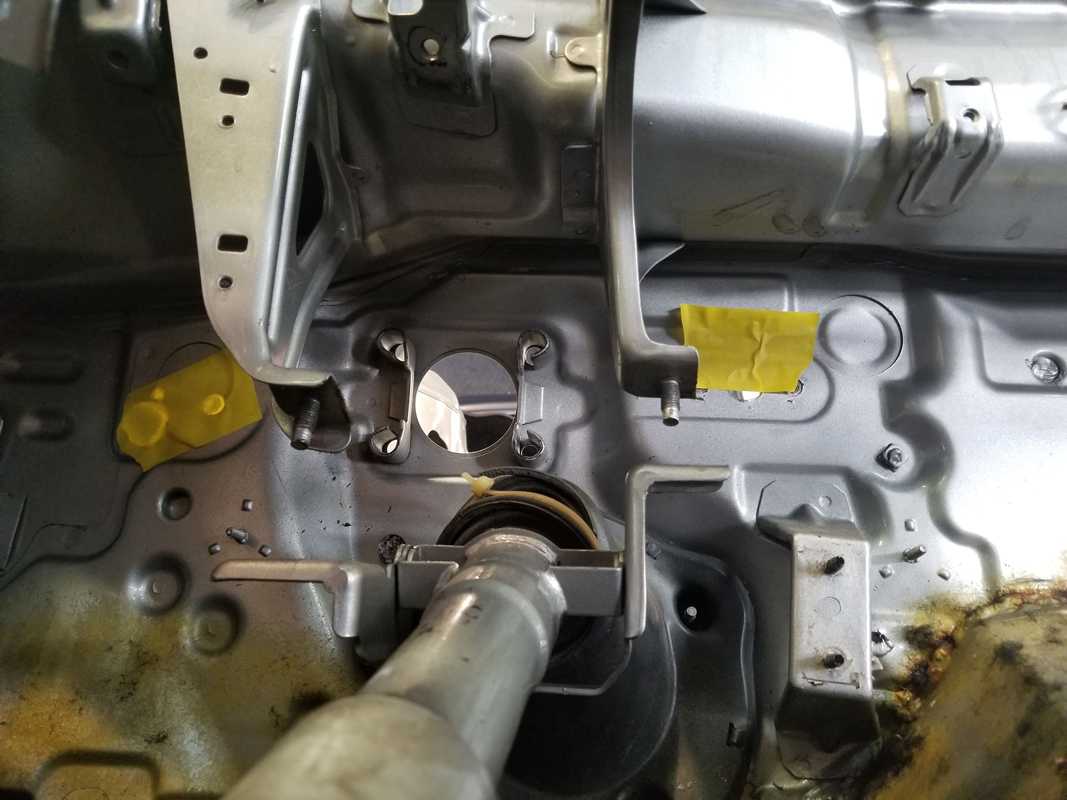

Insert the spacers into the rolled sheet metal where the brake booster used to mount. They should slide in with some ease, but it is often the case that the rolled sheet metal will need to be pried open a little to accommodate the spacer. Loose is better than tight because you don’t want to spacer forcing the screws that will bolt the assembly in place to be forced into misalignment. Opening the rolled sheet metal can be done with a screw driver.

Step 3

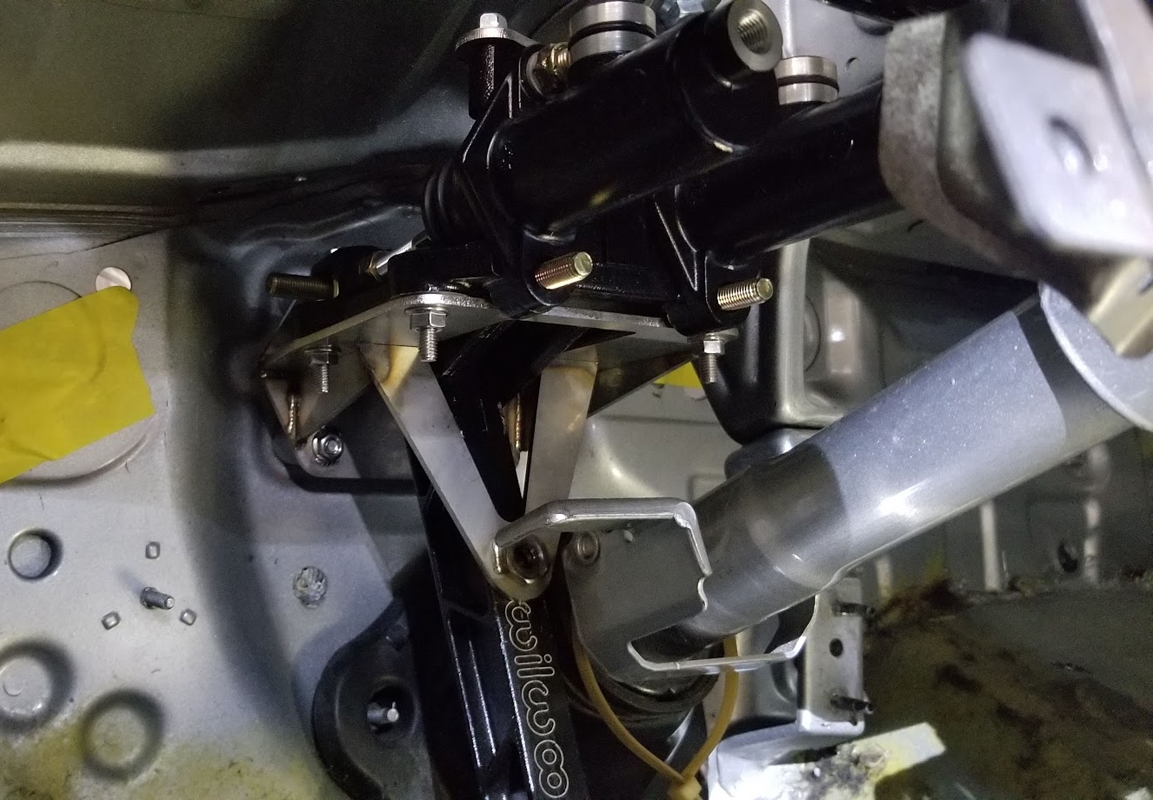

Assemble the brake master cylinders and mount onto the brake master cylinder bracket using the main, top, and lower brackets.

Step 4

Adjust the master cylinder rods so the the pedal will have it’s needed amount of throw without hitting the main bracket. Having the rods extended allows the pedal to come up off the floor when installed and allow the brake switch to be depressed when up all the way. If you don’t extend the rods, the pedal might not lift off the floor enough and could cause the pedal to hit the floor when fully depressed. However, you don’t want the rods extended too much to hit the bracket.

Consult the Wilwood instructions for adjusting the bias bar. You can preset the bar, but to adjust, it might be necessary to remove the assembly or remove the dash again to to fine tune the brakes. Completely read the Wilwood instructions to understand the functionality of the system.

Step 5

Set the firewall block-off plate in place using the 4 counter sink screws. These will not tight yet. They just allow everything to rest in place.

Step 6

Have an assistant help hold the assembly in place while the firewall block-off nuts are tightened. Be careful not to cross thread the screws.

Bolt the upper bracket into it’s sheet metal location as well.

Step 7

Bolt the steering column to the steering column bracket on the car and the steering column bracket attached to the brake master cylinder bracket.

To set the brake pedal switch, it is ok to bend the brake switch bracket a little to accommodate the pedal throw.

The bracket installation is now complete.

-------------------------------------------------------------------------------------------------------------------------------------

The reservoirs can be install in a number of different locations, they can be kept under the dash or mounted inside the engine bay or in the cowl. You must make sure the reservoirs are higher than the inlets to the master cylinders.

Here is an installation of the master cylinders in the cowl. Mounting in the cowl required trimming the plastic brackets and trimming the cowl plastic to accommodate the master cylinders.

Step 1

Mark and trim area where reservoirs will mount. Note: where located in the picture, it had barely enough room for the hose off the bottom of the reservoir to clear the master cylinder assembly. You need to make sure the reservoirs are over far enough to not cause a conflict:

Step 2

Mark and drill holes where hoses will need to run. Make sure holes are large enough that the hoses can pass through without rubbing on the edges. Keep in mind that if you use this method, there is no way to seal the cowl off from the interior of the car unless you add a grommet around the hose sealing off the hole that was drilled.

Step 3

Mark and drill holes in firewall to mount the reservoirs.

Step 4

Clamp the reservoirs to their brackets and attach hose to barb. Note how this bracket is trimmed to allow the reservoir to mount as low in the cowl as possible. Even with it trimmed down, it will still be high enough to stick up through the cowl plastic.

Step 5

Run the hoses through their holes and mount the reservoirs to the firewall.

Step 6

Trim the hose to length, attach the hose to the barbs on master cylinder adapters and clamp the adapters to the master cylinders.

Make sure hoses cannot interfere with the master cylinder operation. This is extremely important!!

Besides these steps, with the reservoirs as high as they are, the plastic will need to be trimmed around the lids. Be careful when installing the hood that it can fully close without hitting the reservoirs and trim the bottom of the hood if necessary.

Keep in mind, when bleeding the master cylinders, this mount position or other mount positions might make the hoses have a high point in them that can trap air. This is usually very simple to bleed out, but care must be taken that all air is removed from the system. Sometime a rapid reverse bleed can force any trapped air out. This is not normally a problem and bleeding mostly very straight forward with the air moving down the line like it is supposed to, but you should keep in mind that it is possible to get air trapped and you should be very careful to make sure your system is set up and bled completely.

You need to consult the Wilwood technical documentation for proper master cylinder sizing, balance bar adjustment and brake pressure measurements. Wilwood is the proper source for brake technical help and these instructions are just here for installation of the bracket and not a good source for brake system functionality or adjustments.